Magnetfinish GmbH

Brünigstrasse 64

6074 Giswil

Switzerland

+41 79 549 57 73

thiel@magnetfinish.com

EMO Hannover 2025

We exhibit our latest

machine generation at the booth of

our long-time partner

Wick AG Hall 11 - E 89

Process

Results

Essentials

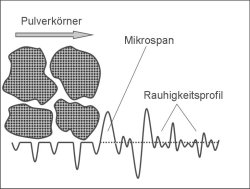

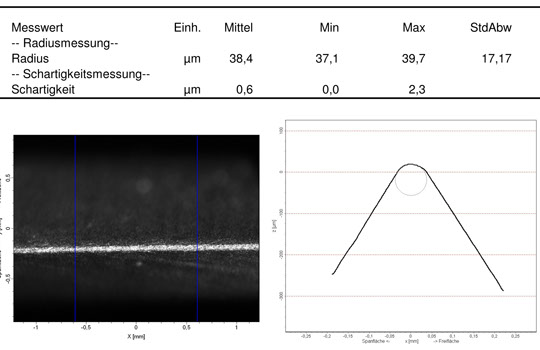

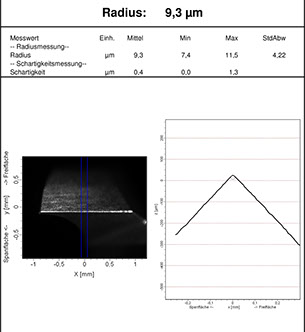

The Magnetfinish(MF) technology is a new mechanical process for technical surfaces. The workpiece is positioned in a magnetic field created by a magnetic disk. The gap is filled with magnetizable processing powder. The powder works during the process as an elastic tool. The hardness of this "tool" may be adjusted by the variation of definite technological parameters of the process. Surfaces will be smoothed till a roughness of Ra = 0,02 micrometers. Edges will get an exactly defined and reproducable radius between 3 and 50 micrometers. With this technology it is not only possible to process magnetic materials (e.g. HSS) but also light magnetic (e.g. carbide) and non-magnetic materials (e.g. Cermet).

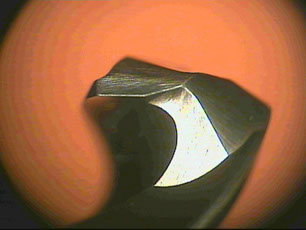

Due to the drecreasing of the surface roughness and the reproducable edgerounding, the Magnetfinish technology is predestined for processing the whole variety of cutting tools. Typical examples are: Taps, endmills, drills, reamers, stamp tools etc. The process can be applied for both tools wich will get a coating layer and tools without getting coatings. Honing of the cutting edges extends the life time and performance of tools very significant. Polishing of the flutes improves the chip flow. When the process is applied to coated surfaces just in a few seconds droplets will be removed and the coating layer will be polished. The coefficient of friction of the tool decreased considerable. Beside cutting tools also components for automotive with special requirements to its surface and complex surface structures are examples for the wide range of applications. Our engineers are continuously testing together with our customers new application areas.

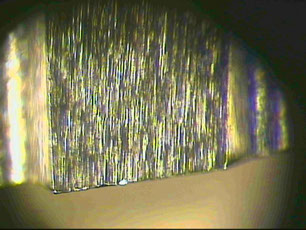

Honing 1

Polishing 1

Polishing 2

Honing 2

Honing 3

Deburring 1

Honing 4

New Pic. 1

New Pic. 2

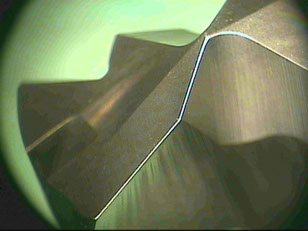

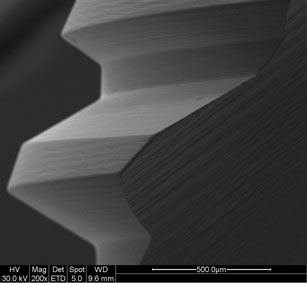

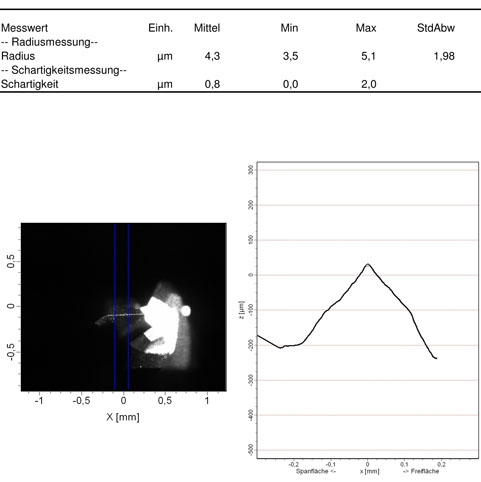

Honed Main Cutting Edge of 3mm Microdrill

Honed Corner Roundmill

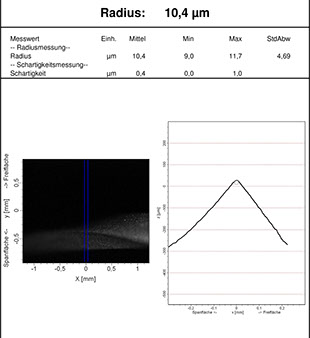

Honed Main Cutting Edge of 16mm Drill, 25 Micron

Honed Main Cutting Edge of 5mm Endmill

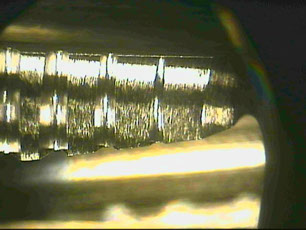

Above: TiN-Coated Tap M8 before Polishing with Droplets

Left: TiN-Coated Tap M8 after Polishing without any droplets

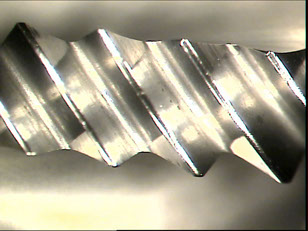

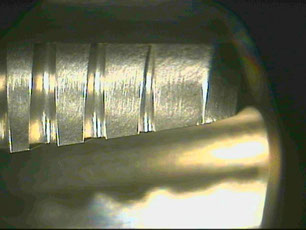

Uncoated Tap M8 before Polishing

Uncoated Tap M8 after Polishing

Uncoated Tap M12 before Polishing

Uncoated Tap M12 after Polishing

Uncoated Tap M12 before Polishing, 2. Tooth

Uncoated Tap M12 after Polishing, 2. Tooth

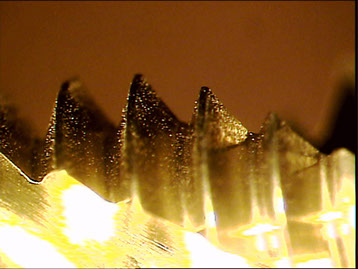

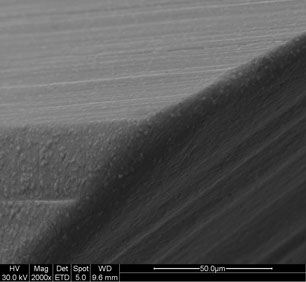

Honed Tap 10mm Magnification 200x

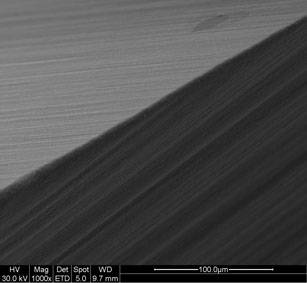

Honed Tap 10mm Magnification 1000x

Honed Tap 10mm Magnification 2000x

Parts from injection system before deburring

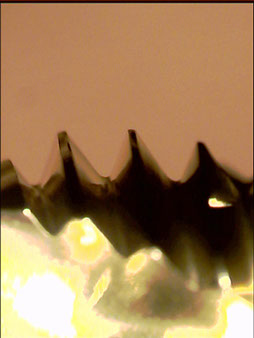

Tap M12, 2. Tooth before deburring

Parts from injection system after deburring

Tap M12, 2. Tooth after deburring

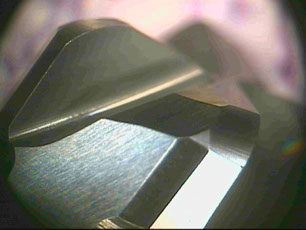

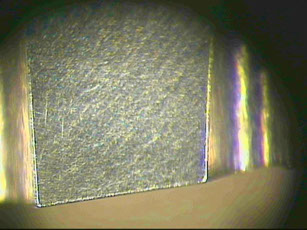

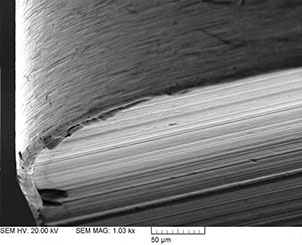

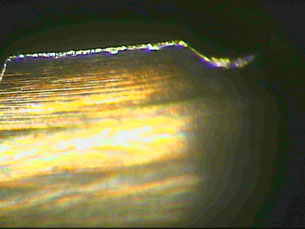

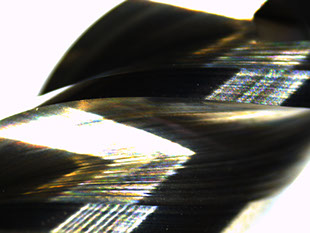

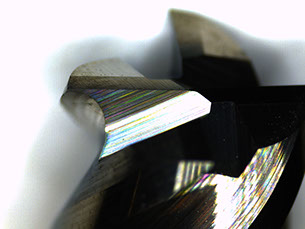

Before MF

Cylinder Cutting Edge of 6mm Square Endmill

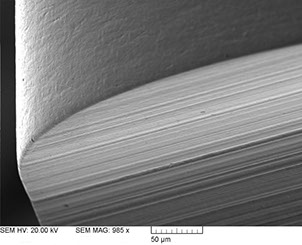

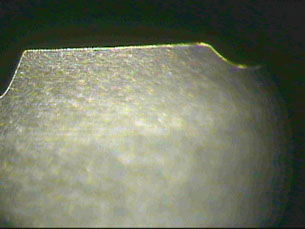

After MF

Honed Square Endmill

After MF

Honed Square Endmill

Before MF

Tip Cutting Edge of 6mm Square Endmill

After MF

Honed Square Endmill

After MF

Honed Square Endmill

- perfect separation of edge honing from polishing and deburring

- consistent quality over the complete tool length

- one gripper for all diameters

- minimal processing time

- 100% reproducable results by continiously refreshing of processing powder

- fullautomized process for different tool types ; automatic adopted parameters

- wear-free processing heads

- no choking up of the cooling channels on drills

- low cost of consumable supplies

Copyright © 2025 Magnetfinish GmbH, Sandra Reichmann, all rights reserved

GENERAL BUSINESS TERMS